Food and Beverage

SKF Food Line Ball Bearing Units

SKF Food Line ball bearing units offer the potential for a relubrication-free solution for most wet, abrasive and contaminating environments. They are available in a range of component designs and variants, to enable the configuration of the bearing unit best suited for various applications and environments. Click here for more information.

Megadyne XMD – Food Safety Metal Detectable and X-Ray Timing Belt

Belt and cleat fragments from all XMD belts can be spotted by metal and x-ray detectors, thanks to a special compound used in the manufacture of the timing belts and their accessories.

This Food Safety feature is in addition to other special hygienic design features that include sealed edges and the use of blue as a contrast colour. Therefore, all Food Contact Timing Belts (open end, endless joined, and truly endless) constructed with this compound are detectable! Click here for more information.

Klüber Speciality Lubricants for the Food Industry

Klüber is proud to support the food industry by engineering specialised lubricating solutions, catering to the specific needs of different machines and applications in the food industry. Keeping food safety and machine efficiency at the highest level. Click here for more information.

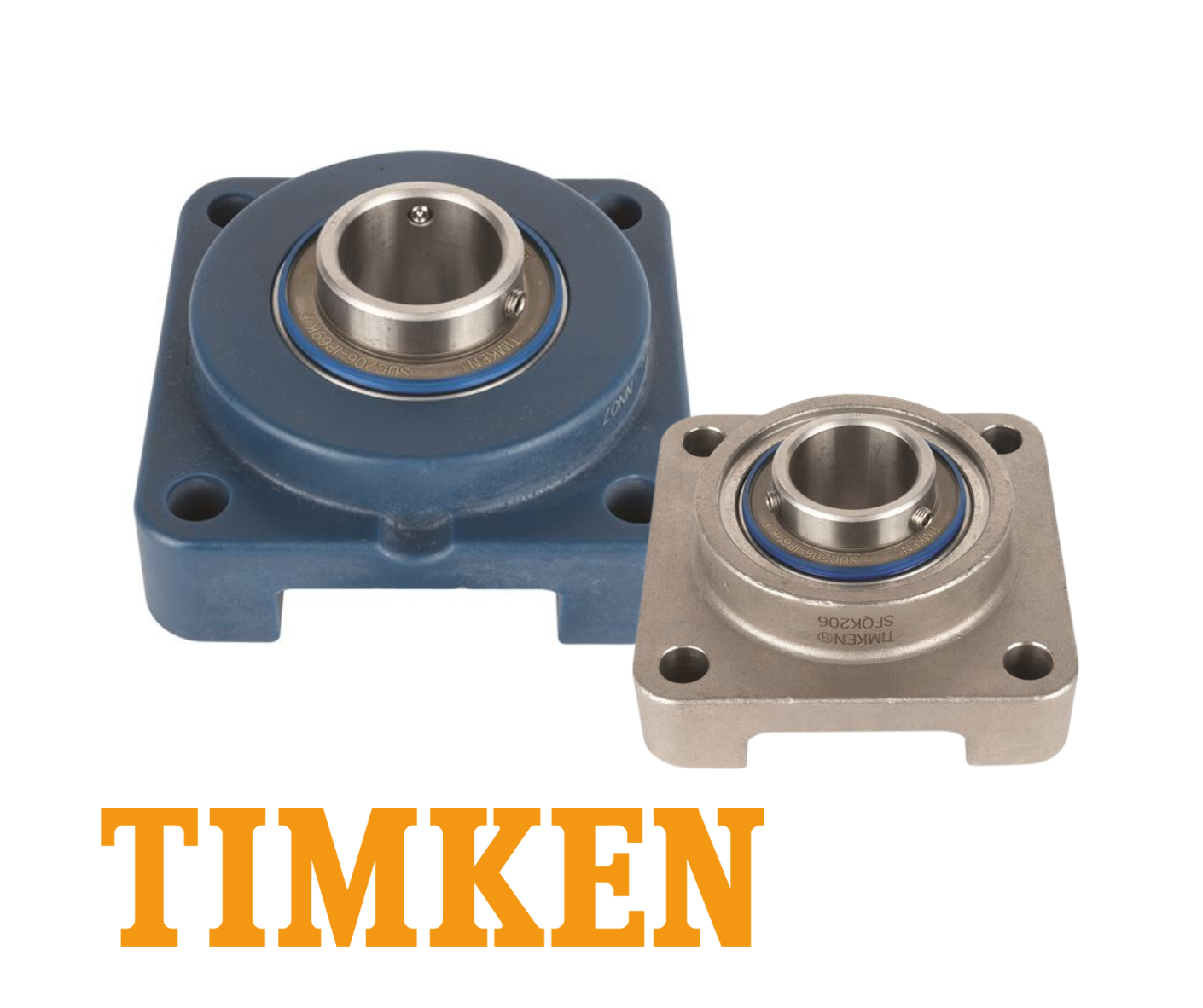

Timken® IP69K Hygienic Mounted Ball Bearings

Heavy washdowns with harsh cleaning chemicals are critical to achieve food safety in food and beverage processing and packaging equipment. Pair that with an abundance of moisture and you risk corrosion to equipment components if they are not properly engineered for this environment.

Timken Hygienic Bearings are specifically engineered to perform in Food and Beverage applications where high-pressure washdowns, high humidity and excessive temperature differences exist. Click here for more information.

Gas Driven Single Point Automatic Lubricators

SKF 24 Automatic Gas Driven Lubricators take the manual labour out of lubrication, ensuring that the correct amount of lubricant is dispensed at the correct interval. This helps prolong the life of machinery, protecting it against contaminants and premature wear.

The units are supplied ready-to-use straight from the box and are filled with a wide range of high-performance lubricants. Tool-free activation and time-setting allow easy and accurate adjustment of lubrication flow. Click here for more information.