Antifriction has grown substantially over the past few years, with 15 branches now across the UK. While this success is exciting from a business perspective, we also understand that every company impacts the environment. The bigger the company, the bigger that impact will be. This understanding led us to take action a few years ago and begin calculating and taking responsibility for Antifriction’s carbon footprint

Antifriction’s Carbon Offset Journey

In 2021, we engaged Carbon Neutral Britain to conduct a thorough carbon audit of our operations. Since then, we’ve continued to work with them to calculate Antifriction’s carbon footprint every 12 months, to ensure we’re taking responsibility for our carbon footprint.

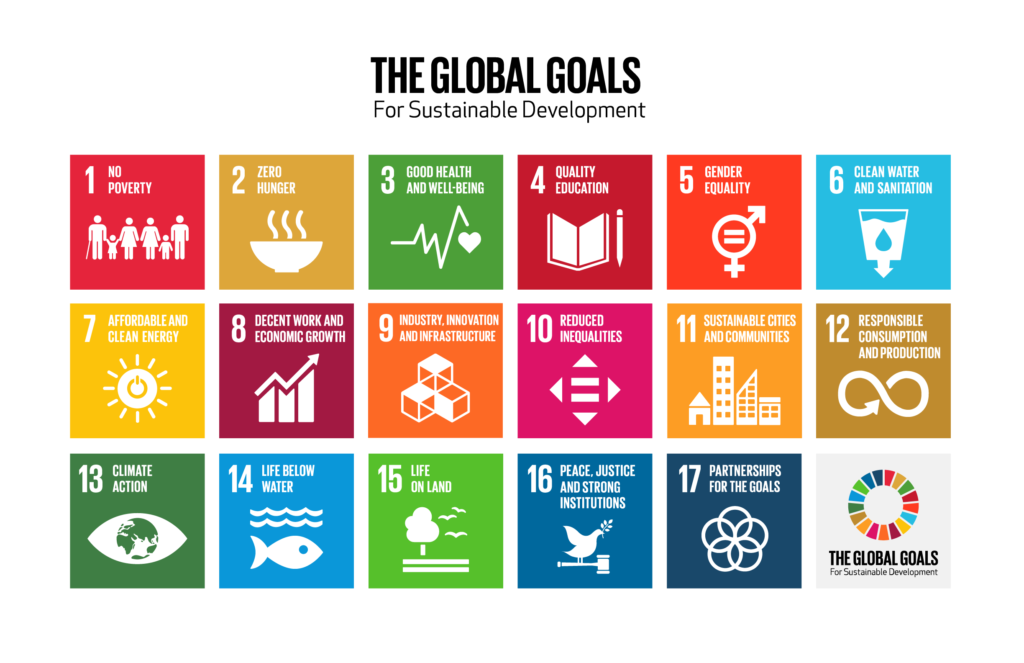

Carbon Neutral Britain is a non-governmental organization (NGO) that helps UK businesses calculate and offset their carbon emissions. The NGO is an advocate for the UN Sustainable Development Goals and allows businesses to support ‘United Nations Certified Emission Reduction Schemes’. With Carbon Neutral Britain’s help, Antifriction officially became a carbon-neutral certified business in 2022.

What carbon offset projects does Antifriction support?

In 2024, Antifriction is supporting four carbon offset projects around the world. These include a hydropower plant in Chile, a wind farm in Mongolia, an energy-efficient light project in India and the Nkhata Bay Cook Stove project in Malawi.

Each of these projects has been designed to meet at least four of the UN Sustainable Development Goals. For example, the energy-saving light project in India helps to provide individuals with affordable and clean energy, while also improving local infrastructure and making cities and communities more sustainable. The project aims to cut CO2 emissions by approximately 35,000 tonnes every year.

You can read more about each of these projects on Carbon Neutral Britain’s website

Antifriction’s Carbon Reduction Plan

As well as offsetting Antifriction’s carbon emissions, we also have plans to reduce the company’s overall carbon footprint. Investing in carbon offsetting projects helps us to take responsibility for Antifriction’s carbon footprint while working to actively reduce the company’s emissions.

In 2022 Antifriction’s management team put together a two-year carbon reduction plan for the business. The plan focused on reducing Antifriction’s energy and fuel consumption, as well as making packaging more environmentally friendly.

Some actions we have taken to reduce Antifriction’s carbon footprint include:

- In April 2022 LED lights were fitted in Antifriction’s UK distribution centres.

- In June 2022, light sensors were fitted at Antifriction’s UK offices and distribution centres, to reduce the overall electricity usage.

- Electric vehicles were introduced to the Antifriction company fleet, with the aim to make the whole fleet electric by the end of 2024.

- In mid-2022 plastic packaging tape was switched to high strength, paper packaging tape.

- All of Antfriction’s packaging is now made from recycled materials.

These are goals that have already been achieved. Antifriction has plans to make more changes in the next few years. Changes the company is considering, include:

- Switching to a greener energy provider, with renewable energy plans.

- Improving insulation in Antifriction’s offices.

- Installing solar panels at the Antifriction head office in Bristol, by the end of 2024.

- Installing more bicycle storage and e-scooter charging points at Antifriction’s head office, to encourage employees to cycle to work.

What difference has Antifriction made?

In 2023 Antifriction reduced its carbon emissions by 11%, despite the business growing by 10% in the same 12 months. We plan to carry on making positive changes and carry on reducing the company’s carbon emissions. We’ll be sure to keep making updates on our progress.

Not only do we prioritise reducing the carbon footprint within our business operations, but we also focus on helping our customers do the same by helping them optimise their machinery, which is summed up in our strapline, Optimise Uptime and Energy Efficiency! Our future plans aim to build on this, giving our customers actionable plans to save energy, reduce their carbon footprint, and do their part in helping the environment.

Working with brands that make a difference

As a specialist in sourcing high-quality, industrial components, Antifriction is partnered with multiple manufacturers. We are proud to say that we work with world-renowned brands that are seeking to reduce their environmental impact and pioneer sustainable developments in their field.

For example, respected adhesive brand, Loctite, has in recent years put a great deal of investment and research into improving the health and safety of its products. Our adhesives & lubrication partner Loctite now offers a range free from Hydroquinone, a chemical that is harmful to both human health and marine life.